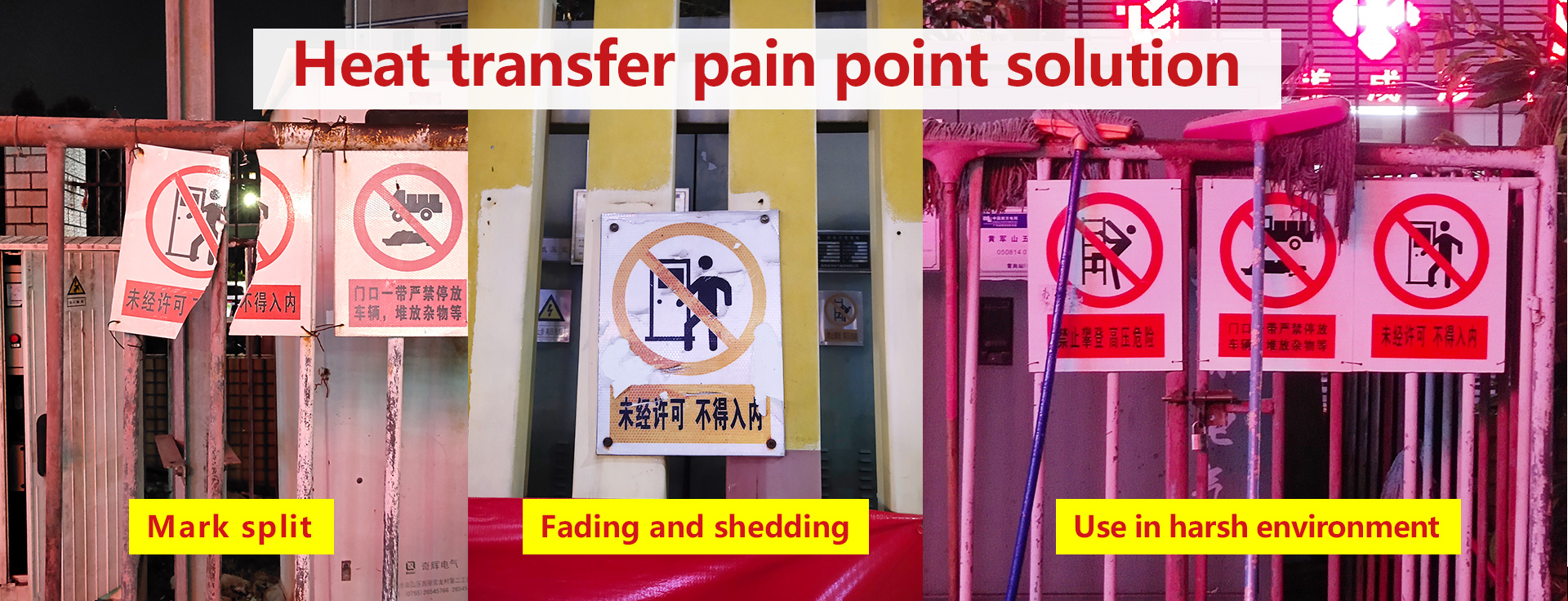

Advantages of thermal transfer printer scheme:

1. Mature printing technology to ensure high reliability and high availability;

2. High-quality printing, the logo printing is clear, eye-catching and colorfast;

3. No cracking, corrosion resistance and scratch resistance when used in harsh environment;

4. Thermal transfer equipment is compact and durable, easy to operate, without maintenance.

Thermal transfer printing technology

A special multilayer ribbon is installed between the print head and the bracket of the thermal transfer printer. Heating elements are integrated on the print head to ensure the printing effect of each pixel. The heating elements are controlled by a computer, distributed in dots and arranged in a straight line on the print head. The heating element can dissolve the color layer and transfer the image to the component to be marked in rows.

The whole process is flexible and fast. This process requires a good surface finish of the component to be marked, so that the color ribbon can be completely adhered to the component. The thermal transfer printer is suitable for printing soft materials, such as strong adhesive nano polymer PVC label, PVC, 0.45mm aluminum alloy, etc.

Thermal transfer printing carbon ribbon

Ribbon is a key component of thermal transfer printer, which contains multiple color layers. The design of the back coating can prevent its abrasion as much as possible, reduce electrostatic charge and protect the print head. The back coating is covered with PET film with thermosensitive color layer.

Wax-based carbon belt

1. mainly suitable for paper printing materials

2. Clear images can be printed on the rough material surface

3. Low scratch resistance 4. Low printing energy consumption

Resin carbon belt

1. Suitable for printing film and plastic surface

2. The printed image is resistant to high temperature and scratch

3. The printed image has strong durability and is resistant to solvent and chemical corrosion

4. The dissolution temperature of this ribbon is higher than that of wax ribbon, which requires the printing head to have stronger heating ability and slower printing speed.

5. Heat transfer printing requires higher energy consumption

Mixed carbon belt

1. integrating the advantages of wax ribbon and resin ribbon

2. Suitable for printing paper and plastic

3. The printed image is scratch resistant and heat resistant

4. Compared with pure resin ribbon, the solvent resistance and chemical corrosion resistance are slightly worse

5. Fast printing can be realized, which is suitable for various applications

6. Moderate printing energy consumption

Heat transfer printing head

Print head is one of the most important components of thermal transfer printer. The print head contains several heating elements which can be individually controlled electrically. The heating element can dissolve the color layer on the ribbon and transfer the color to the printing material. The number or density of heating elements on the print head and the temperature conversion frequency determine the resolution of the printed image. Different types of print heads have different arrangements of heating elements.

Brand of thermal transfer printer

MASUNG, a manufacturer of Shenzhen thermal transfer printer brand, provides an overall solution for printing logos, labels and labels. the thermal transfer printer MS-TTR362AC sells well, which can not only print PVC materials, but also print aluminum alloys, and is a good helper for making logos.

Copyright © 2012 - 2022 ShenZhen Masung Intelligent Equipment Co., Ltd. All Rights Reserved.

Skype

jason-pong

Click to ChatSkype

amy-cj3

Click to Chat+86-13302989900

Click to Chat+86-15399991274

Click to Chat